|

1. Ceramic raw materials 1. Ceramic raw materials

Divided into porcelain clay and glaze, the raw materials are basically the same, but the ratio of raw materials is different.

Its main components: feldspar, quartz, zinc oxide, zirconia, aluminum powder, magnesium oxide, colorants.

K2O Si O2 ZnO ZrO2 AI2O3 MgO

Clay: A type of clay used to produce pottery and porcelain.

Porcelain: A finished product that is completely vitrified into porcelain during high-temperature firing.

Ceramic: A finished product that is not completely vitrified in high temperature firing.

The difference between porcelain and pottery: raw material formula, product and water rate, firing temperature.

Slurry: The raw material used for forming grouting.

Glaze: The raw material used for semi-finished glaze.

Production process: ball milling, filtration, iron removal, pool storage.

Ball milling and sieving must reach 325 mesh international.

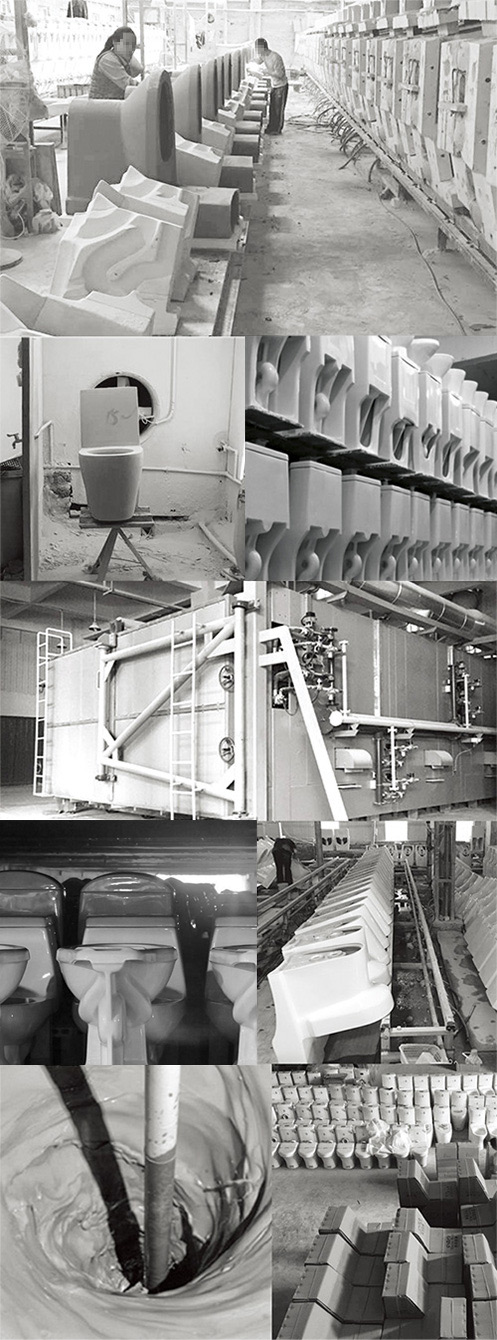

2. Mold

Gypsum mold for forming grouting.

Material: Gypsum powder.

Features: fast water absorption, short solidification time, easy repair and low price.

Grouting times: 80 times - 100 times.

Production process: 3D drawing design, original model artificial sculpture, each mold is made of resin as a master mold, and the sub-mold produced by the master mold is used for forming grouting.

3. Molding perfusion

The slurry is used to form a semi-finished product in the plaster mold.

At least two models of each molded product are combined.

Molding method: single-sided suction, double-sided suction.

Production process: grouting, slurrying, demoulding, splicing and punching, repairing.

4. Spray glaze

The glaze is evenly sprayed on the semi-finished product.

Spray glaze method: machine hand spray glaze, artificial spray glaze.

5. Firing

A semi-finished product that has been sprayed into a glaze and formed in a crucible after a certain period of time has been heated at a high temperature.

Firing shrinkage rate: no more than 1.15.

Firing time: 13 hours - 15 hours.

Firing temperature: 1210 ° C - 1280 ° C.

Firing process: pre-tropical zone, firing zone, cooling zone.

Various types of furnaces: shuttle rafts, tunnel rafts, roller rafts.

6. Inspection

Development room: slurry: fineness, specific gravity (water content), shrinkage, strength, bending resistance, flow, thixotropic.

Glaze: flow, thixotropic, fineness, specific gravity, color difference, high waterfall flow, drying time, glaze adaptability (in order to control thermal stability).

Chromatic aberration: compared with international standard swatches for producing tiles on glaze and firing, imported color aberration meter is adopted.

Color: Visual inspection.

|

|